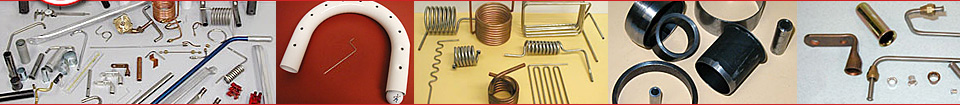

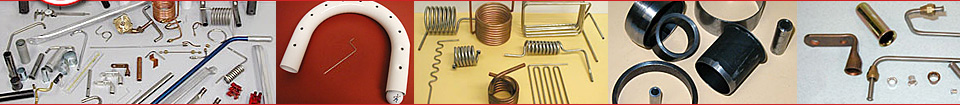

| Capabilities/Products Tube Bending Tube End Forming Tube Assembly Tube Cutting Hypodermic Tube Fabrication Lubricating Oil Cups Tube Coiling Metal Tube Spacers Tube Swaging Custom Miniature Heaters |

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Site created by ThomasNet Web Solutions

Site created by ThomasNet Web Solutions |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||